DC POWER CORDS

Reasons to Engage Your DC Power Cords

DC power cords are electrical cables used to connect two DC devices or a DC device and a DC power source. They are also known as DC power cables. There are many types of DC products, examples include DC power extension cords, DC power supply cords, DC power adapter cords, and DC power splitter cords. They are ideal for CCTV Security Cameras, Routers, or any application that requires connectivity with power.

A DC power supply cord is used to connect a power supply to a device that uses DC power. They are available in different lengths and can have either two or three prongs. DC power extension cord is used to extend the length of a standard DC cord. It has a plug on one end and one or more sockets on the other. Typically, each end of the cord uses the same type of connector. By contrast, a DC power adapter cord has a different type of plug or receptacle on each end. In this article by cord manufacturers, features, benefits, parameters, and applications of DC power cords will be discussed.

New Products

Main Products

Product Name Product Name

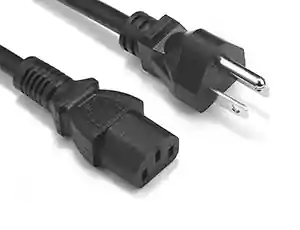

American Power Supply Cable 1.5m 3 Prong NEMA 5-15P US Plug IEC C13 IEC

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

Product Name

Power Cords Use Case

Extension Cord for IP Camera?

What would be a safe (as in adhering to the electrical code and won’t start a fire or even just damage the camera) solution to the short power cord?

Use a DC power extension cable, one end female, the other end male, that will extend the 12V DC further to your IP camera. Make sure your DC extension cord is certified by either CSA and/or UL(C) and it should be safe enough to use. Make sure it’s not subject to water, elevated humidity, direct heat, etc.

Benefits of Cigarette Lighter Socket

Access to 12V power. The primary benefit of a cigarette lighter socket is that it gives you the ability to tap into the vehicle’s existing energy source to miscellaneous power equipment.

Preserve resale value. Keeping up with basic maintenance is essential to preserving the value of the car. If any of the ports need replacing in your vehicle, you should do so because of this factor.

Custom look. 12-volt power sockets come in a variety of shapes and sizes. It may not be a primary reason to buy one, but that gives you the option to use one to compliment the look you’re working to achieve.

USB to DC Connector

USB power extension cord compatible with all USB interfaces with an output voltage of 5v.

- Digital Alarm Clock

- Light Sunrise Alarm Clock

- LED Head Lamp

- Display Wake Up Light

- Mini fan

- Serato DJ Controller

DIY Electronics Testing

Most DC power supply equipment input voltage needs AC power cords, DC power as the output voltage with a DC extension cord. When we use power supply equipment for testing, personal DIY, product maintenance, or laboratory teaching maybe need different DC power cables according to the project requirement.

For example, for the above equipment, the different applications may require different DC power cords.

DC power cords are electrical cables used to connect two DC devices or a DC device and a DC power source. DC power cords are also known as DC power cables.

dc power cord for xx

What Are DC Cords Used for?

There are many types of DC power cords. Examples include DC power supply cords, DC power splitter cord, pigtail DC power cords, DC power extension cords, and DC power adapter cords. A DC power supply cord is used to connect a DC power supply to a device that uses DC power. DC power supply cords are available in different lengths and can have either two or three prongs.

dc power extension cord

A DC power extension cord is used to extend the length of a standard DC power cable

A DC power extension cord is used to extend the length of a standard DC power cable. It has a plug on one end and one or more sockets on the other. Typically, each end of the cord uses the same type of connector. By contrast, a DC power adapter cord has a different plug or receptacle on each end.

DC Cord Features

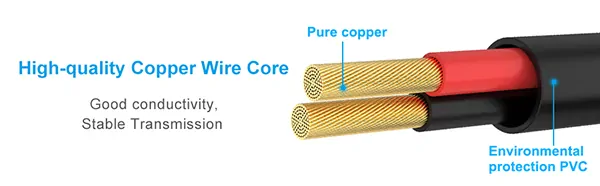

Necessary specifications to consider when searching for DC cords include cord length, wire shape, jacket material, maximum cable temperature, rated current, and rated voltage. Cord length is measured in feet or meters and includes both connectors, and the wire shape can be flat or round. Maximum cable temperature is measured in degrees Fahrenheit or degrees Celsius. Choices for jacket material include polyvinyl chloride (PVC) and rubber.

PVC is suitable for indoor use. A rubber jacket is used when DC power cables are subjected to mechanical stresses in dry and damp areas. All DC power cords have an outer jacket to protect and insulate the wire. Some DC power supply cords, DC extension cords, and DC adapter cords may carry additional specifications.

What Common Approvals for DC Power Cables?

Common approvals for DC power cables include the CSA Mark and the UL Mark. Power cords that bear a CSA Mark have been tested by the Canadian Standards Association (CSA) and meet applicable standards for safety and performance. Underwriters Laboratories (UL) is a non-profit organization that tests materials, components, and systems according to its published standards for safety.

If products receive UL approval, they will bear a UL mark. These standards are written and administered by organizations such as CSA International, Underwriters Laboratories (UL), American National Standards Institute (ANSI).

According to the appropriate Canadian criteria, CSA Marks that show up alone are made use of products accredited primarily for the Canadian market. CSA Marks that appear with the signs “C” as well as “US” or “NRTL/C” are used with products licensed for both the US as well as Canadian markets, to the relevant US and Canadian standards. Other qualifications and also approvals for DC power cables are additionally available.

The Difference Between AC and DC

Alternating current (AC) and direct current (DC) are notable for inspiring the name of an iconic metal band, but they also happen to sit right at the center of the modern world as we know it. AC and DC are different types of voltage or current used for the conduction and transmission of electrical energy.

Electrical current is the flow of charged particles, or specifically in the case of AC and DC, the flow of electrons. According to Karl K. Berggren, professor of electrical engineering at MIT, the fundamental difference between AC and DC is the direction of flow. DC is constant and moves in one direction. “A simple way to visualize the difference is that, when graphed, a DC current looks like a flat line, whereas the flow of AC on a graph makes a sinusoid or wave-like pattern,” says Berggren. “This is because AC changes over time in an oscillating repetition — the up curve indicates the current flowing in a positive direction and the down curve signifies the alternate cycle where the current moves in a negative direction. This back and forth is what gives AC its name.”

Leaving aside lines and graphs for a moment, Berggren offers another way to distinguish between AC and DC by looking at how they work in the devices we use. The lamp next to your bed, for example, uses AC. This is because the source of the current came from far away, and the wave-like motion of the current makes it an efficient traveler. If you happen to be a read-by-flashlight kind of person, you are a consumer of DC power. A typical battery has negative and positive terminals, and the electrical charge (it’s those electrons) moves in one direction from one to the other at a steady rate (the straight line on the graph).

Interestingly, if you’re reading this on a laptop, you are actually using both kinds of current. The nozzle-shaped plug that goes into your computer delivers a direct current to the computer’s battery, but it receives that charge from an AC plug that goes into the wall. The awkward little block that’s in between the wall plug and your computer is a power adapter that transforms AC to DC.

Berggren explains that AC became popular in the late 19th century because of its ability to efficiently distribute power at low voltages. Initially, power is conducted at very high voltages. In order to get these high voltages down to the low voltages necessary to power, say, a household light bulb, it’s necessary to transform the current. A transformer, which is basically two loops of wire, gets AC down from hundreds of thousands of volts to distributions of reasonable voltages (in the hundreds) to power most day to day electronics. The ability to transform voltages from AC meant that it was possible to transmit power much more efficiently across the country.

According to Berggren, there’s a funny history of rivalry between AC and DC. In the later 19th century, there was a giant war between Edison and Westinghouse over AC and DC. Edison had patents in place that made him invest in the widespread use of DC. He set out to convince the world that DC was superior for the transmission and distribution of power. He resorted to crazy demonstrations like killing large animals with AC in an attempt to prove its terrible dangers. For a time, he was successful and, most municipalities utilized local power plants with DC supply. However, getting power to less populated, rural communities all over the country with DC proved very inefficient, so Westinghouse ultimately won out, and AC became the dominant power source.

How Do You Identify a DC Power Connector?

There are many standards for dc connectors and perhaps even more versions of non-standard connectors. The standard connectors we will discuss are barrel connectors, DIN connectors, and USB connectors.

Some of the features associated with the three categories of dc output power connectors are listed below:

| Barrel Connectors | DIN Connectors | USB Connectors |

| Standardized | Standardized | Standardized |

| Inexpensive | Higher current capability | Compact |

| No Orientation required | Durable | Signal transmission |

Barrel Connectors

Barrel connectors are perhaps the most common design for dc power connectors because they are inexpensive to manufacture due to loose mechanical tolerances and have no required orientation when plugging them together.

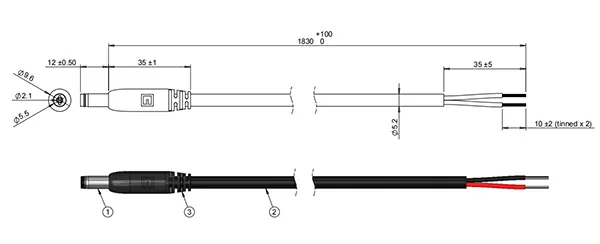

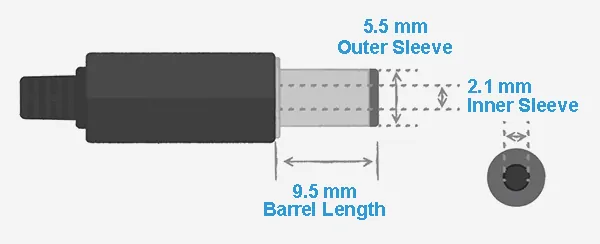

The most common form of barrel connectors has plugs constructed with concentric metal sleeves (barrels) separated by an insulator. Many standard diameters are available for both the inner and the outer sleeves and the length of the plug barrel. Typical combinations of the diameters and lengths exist, but the design engineer will still need to specify the desired dimensions for the plugs used in their products.

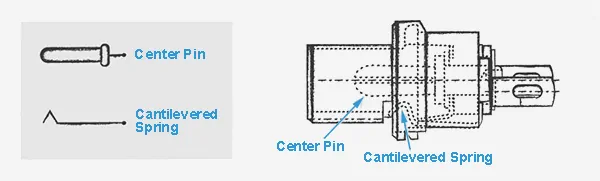

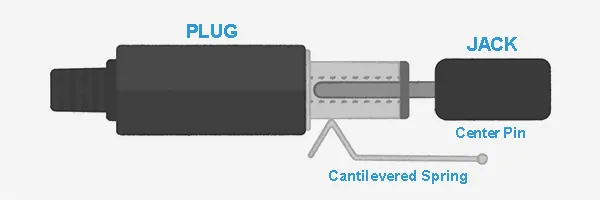

The corresponding barrel jack has a pin, which fits into the inner sleeve of the plug, often with a loose mechanical clearance and a cantilevered spring that contacts the outer sleeve of the plug. Like the barrel plug, the barrel jack will have dimensions for the central pin diameter, the inner case diameter, and the plug insertion depth.

When the barrel plug is inserted into the jack, the spring in the jack pushes against the outer sleeve of the plug and forces the central pin on the jack to contact the inner sleeve of the plug. The selection of plug and jack dimensions needs to ensure the desired mechanical fit is achieved and the proper electrical connections are established.

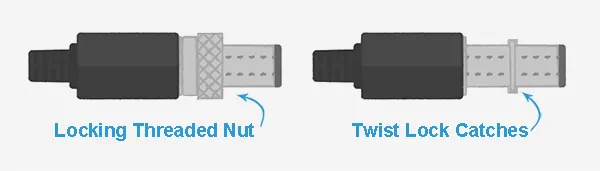

Although the features of the barrel connector make them appropriate for many applications, there are also some issues caused by the design of barrel connectors. The mechanical tolerance between the central pin on the jack and the inner sleeve on the plug is not standardized. Similarly, the force with which the cantilevered spring in the jack pushes against the outer sleeve of the plug is not standardized. This lack of standardizations means that the insertion and retention forces between the plug and the jack are difficult to specify and vary over a wide range. In standard barrel connectors, there is no mechanical retention mechanism for the connection, and thus the connection can accidentally come apart. A solution to ensure the connection is retained is to use locking barrel connectors. Locking barrel connectors are available with either threaded or twist locking features.

The current rating of barrel connectors is determined by the force and surface area between the cantilevered spring and the outer sleeve and between the inner pin and the inner sleeve. The light forces and small surface areas limit the current ratings of the connectors.

Barrel connectors are available in a range of both inner and outer conductor diameters. Although there are no standards for the combinations of inner and outer diameters, product designers may choose to specify dimensions to either match existing products or to be unique from other products. The two most common barrel connector sizes are 5.5 mm outer sleeve diameter with 2.1 mm inner sleeve diameter and 5.5 mm outer sleeve diameter with 2.5 mm inner sleeve diameter.

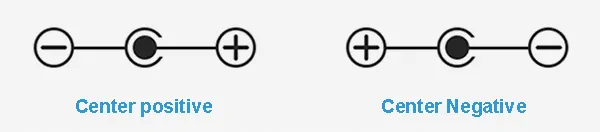

Convention has evolved with the outer conductor as the ground or negative voltage and the inner conductor as the positive voltage. The advantage of this configuration is if the outer plug of the sleeve touches an exposed conductor, then the exposed conductor will be connected to the ground rather than to any other electrical potential. This convention is not always followed, and some product design teams place the positive potential on the outer conductor and the negative potential on the inner conductor.

Selecting the power cord to be in line with the power connector is the most common configuration used in the industry. This configuration is easy to manufacture and makes it more convenient for the user to align the connector when mating. However, there are applications where a right-angle plug configuration may be preferred. One reason for selecting a right-angle plug may be to allow the dc power cable to remain closer to the chassis as it feeds into the plug and thus allowing the physical footprint of the product to be smaller. Another reason for selecting a right-angle plug is to provide for retention between the two halves of the barrel connection. Because the power cord is at right angles to the connector, a force putting tension on the cord will force a torque on the barrel connector, which will make it more difficult to disengage the connector. It is also possible to secure the cord under a hook or latch on the product case such that none of the tension force on the cable is transferred to the plug.

DIN Connectors

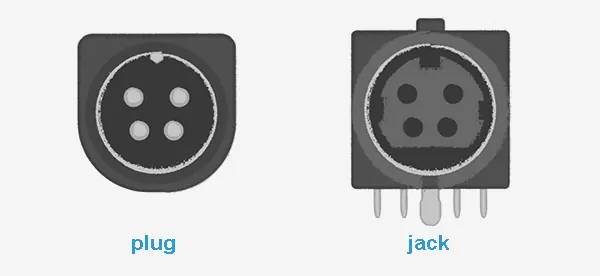

DIN power connectors are a style of connectors with four-pin or socket contacts encased in a circular housing. These connectors were originally defined by a German standards organization (Deutsches Institut fur Normung), and thus the name of DIN connectors but are now defined by IEC 60130-9. Power DIN connectors are often used in moderate power applications when barrel connectors are not able to carry the required current. Confusion often exists between power DIN connectors and signal DIN connectors. There is not an absolute definition of a power DIN connector, but by convention, power DIN connectors have four contacts spaced at approximately 90 degrees around the center of the connector. Although the dimensions of the pins and connectors are difficult to find in the documentation, it can be assumed 4-pin DIN power plugs and jacks connect properly. Power DIN connectors can also be found with a threaded locking feature, like the barrel connectors.

USB Connectors

USB connectors were originally developed to deliver dc power and digital signals. The wide acceptance of the USB power voltage level and connectors has also made them popular for power-only applications. The Type-A connector is perhaps the most popular USB connector at the present time and can be found in applications requiring 5 Vdc with current load levels of less than about 2 A. Variations of the USB Type-A connector (mini, micro, etc.) are also used in similar power delivery applications. One limitation of the Type-A connector and the variants is there is only one orientation of the connectors in which they will properly connect. This limitation requires the user to determine the correct orientation of the plug and jack either by visual identification or by attempted insertions.

The USB Type-C connector is more compact and can be inserted in either of two obvious orientations. The Type-C connectors can pass higher power levels than previous versions of the USB connectors and are rated to deliver a maximum of 20 V at 5 A. Although product designers can choose any connector for the dc power plug, many electronic products use USB input power jacks to receive 5 Vdc. Because of this common practice, it is prudent to use USB plugs only on power supplies with a 5 Vdc output voltage rating to not damage the many products using USB power jacks that are expecting 5 V from the plug. The exception to this recommendation is if a USB Type C connector is used, then the USB PD and PPS specifications allow for the supply and load to negotiate for a voltage between 5 V and 20 V.

In addition to the electrical characteristics of the input and output voltages and currents of power supplies, connectors also must be specified for the supplies. Ac input connectors are reasonably well standardized and thus limited in selection for the intended power levels and international markets. In contrast, dc output connectors are not as standardized, and thus the designer has many more decisions to make. The output dc power plug should be rated for the output voltage and current and must conform to the desired mechanical characteristics of the product. DCpowercord has technical and sales support staff who can help to advise on power connector decisions for power supplies. Sourcing Guide for DC Power Cord DCpowercord would provide all of your DC power cord requirements; You are sure to find what you need in our products catalog. Amongst the wide range of products for sale choice, DC power cable is one of the hot items. Design engineers or buyers might want to check out various DC power cord factories & manufacturers, who offer many related choices such as power cord and cable. You can also customize DC cord orders from us; we support OEM/ODM manufacture. We have experienced China exporters for your online sourcing. Update your electrical products and buy from us, a credible supplier with the latest China production technology. We hope to keep every buyer up to date with this fastest-moving electronic industry and the latest products trends. You can also call or email us and get some buying guides.

GET A FREE QUOTE FOR YOUR PROJECT

Our team is ready to support your next project, so contact us today!